- Home

- Insights

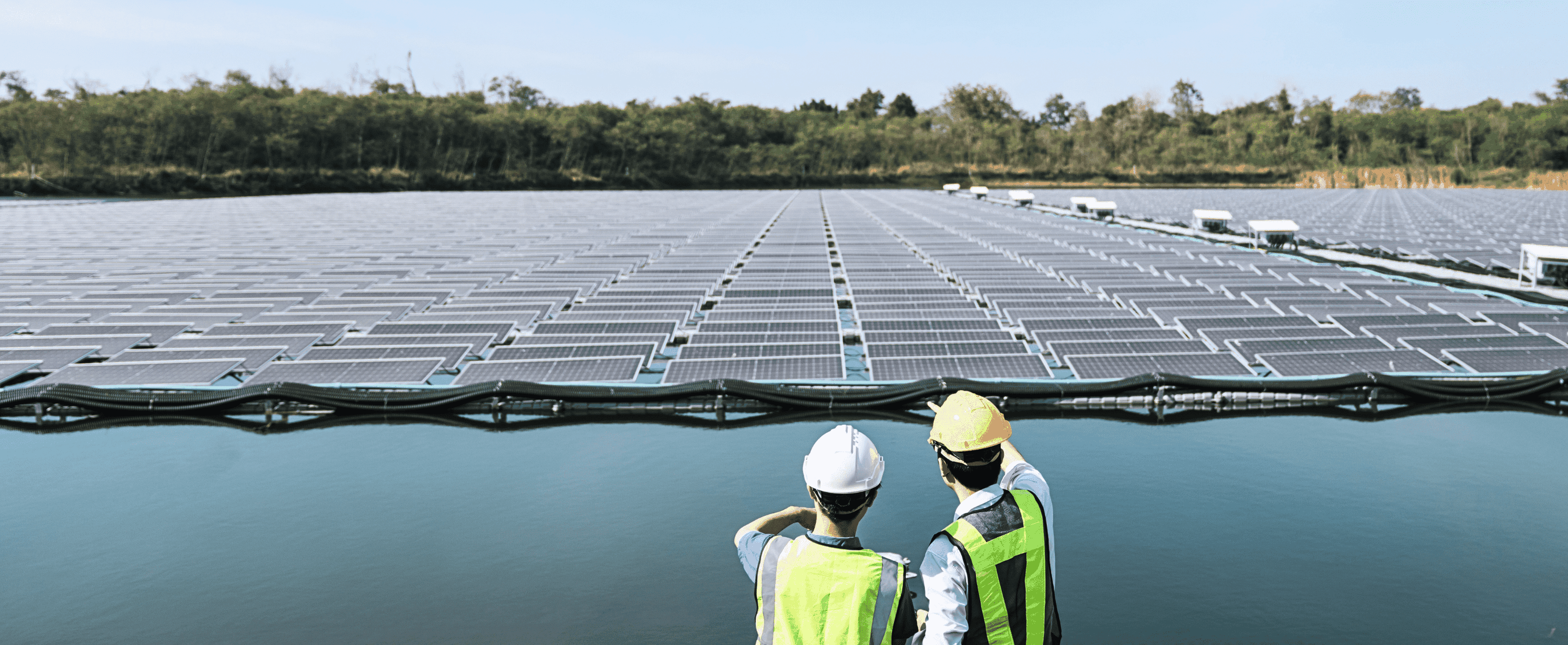

Technical requirements for solar cables in floating PV applications: Standards, tests and challenges

Floating PV systems, i.e. solar systems that are installed on water surfaces, are becoming increasingly important. They not only offer a solution for land use on bodies of water, but also enable more efficient energy generation, as the cooling effect of the water increases the output of the solar modules. However, the specific conditions on the water place high demands on the technical components - especially the cabling.

Special requirements for solar cables in floating PV applications

Solar cables used in floating PV systems must withstand various conditions. These conditions are largely determined by the installation on water and differ significantly from the requirements for cables in land-based solar projects.

Moisture and corrosion protection

Cables in floating PV systems are exposed to constant contact with water. Moisture is a key risk factor that corrodes the cables and their insulation. To ensure long-term reliability, the cables must be resistant to corrosion, especially the outer layer of the cables. Otherwise, chemical influences such as salts, minerals and other components in the water could damage the cables.

Mechanical loads and flexibility

Wave movements, temperature fluctuations and the constant oscillation of the modules can lead to mechanical stresses. The cables must be both robust and flexible enough to withstand the dynamic environment in the water. This requires special materials and manufacturing processes.

UV radiation and weather resistance

Solar cables in floating PV systems are also exposed to intense UV radiation. Cables must therefore be equipped with insulation that is not only UV-resistant, but also resistant to other weather conditions such as rain, snow and extreme temperatures.

Standards and tests: Guarantees for safety and reliability

Specific standards and test procedures are required for the safe and long-lasting operation of floating PV systems. These ensure that the cables work reliably under the special environmental conditions on the water.

Standards for corrosion resistance

Cables in floating PV systems are particularly susceptible to corrosion due to constant contact with water. A relevant standard for this is EN 50618, which sets out requirements for photovoltaic cables. This standard defines how cables for use in PV systems must be designed and tested to ensure high corrosion resistance and durability. It ensures that the cables work reliably under extreme conditions such as those found in floating PV systems due to moisture and salt water.

Tests for UV resistance

Cables in floating PV systems are exposed to a wide range of weather conditions, including intense UV radiation. To test resistance to the harmful effects of UV radiation, the IEC 62930 standard is relevant, which describes the requirements for PV cables with regard to their environmental resistance. This test is essential because the cables are exposed to both direct UV radiation and indirect radiation caused by the reflection of the water. The standard requires that cables must be designed in such a way that they do not suffer significant damage or degradation under prolonged UV exposure that could affect their safety or electrical properties. This includes preventing cracking, brittleness or loss of insulation due to UV radiation.

Testing of mechanical properties

Floating PV systems are exposed to particular mechanical stresses, particularly due to wave movements and temperature fluctuations. To ensure that the cables can withstand these conditions, the TÜV 2 Pfg 2750/09.2020 certification is important. This standard includes tests for fire resistance, mechanical strength and tensile load. It ensures that cables in floating PV systems do not fail even under extreme movements and mechanical loads.

In North America, UL44 is an important standard for cables. It specifies requirements for the construction, insulation and mechanical strength of cables, which ensure that the cables work reliably under various loads.

Fire and safety standards

Another crucial safety factor for floating PV systems is fire resistance. The IEC 61439-1 and IEC 61439-2 standards deal with the requirements for low-voltage switchgear and distribution boards. They contain test requirements to ensure the safety of these systems, especially with regard to fire protection. The TÜV 2 Pfg 2750 standard mentioned above, which was developed specifically for floating PV applications, ensures that the cables retain their fire safety and electrical properties even under extreme temperatures and in direct sunlight. To this end, it includes tests on the fire resistance of the cables in order to minimize possible fire risks.

The UL1581 and UL2556 standards are important for the North American market. UL1581 is a testing and certification standard for cables and wires in a wide range of applications, including photovoltaic systems. It includes a series of tests for fire resistance, temperature resistance and mechanical strength to ensure that cables can withstand extreme conditions. The UL2556 standard, which was developed specifically for cables in photovoltaic systems, ensures that these cables operate safely and reliably under extreme environmental conditions.

Challenges in installing solar cable

In addition to the technical requirements and standards, other challenges must be taken into account when installing solar cables for floating PV systems:

Long-term reliability under extreme conditions: Floating PV systems are difficult to access and cable maintenance is even more difficult on the water. To minimize downtime and expensive repairs, the cables must be durable, reliable and low-maintenance.

Easy installation and robust cable management: To facilitate installation and maximize system efficiency, cables and connections must be easy to handle and install. Cable management solutions such as prefabricated cable drums or cable harnesses as a plug-and-play solution support simple and safe installation and maintenance.

HIS products for floating PV: certified, tested and verified

For the special requirements of floating PV systems, we offer you certified products that meet all relevant standards and test requirements. Our HIKRA® SOL cables, HISkon® cable harnesses and HISbox® string boxes are specially designed for the extreme conditions on the water.

HIS product quality: certifications and standards

HIKRA® SOL cables: TÜV 2 Pfg 2750 certified

HISkon® cable harnesses: EN50618, IEC62930, UL44, UL1581 and UL2556 standardized and certified according to TÜV 2 Pfg 2750/09.2020

HISbox® string boxes: IEC 61439-1 and IEC 61439-2 standardized